- TILTROTATOR

- FLEXIBILITY

- CONTROL

- SENSORS

- ATTACHMENTS

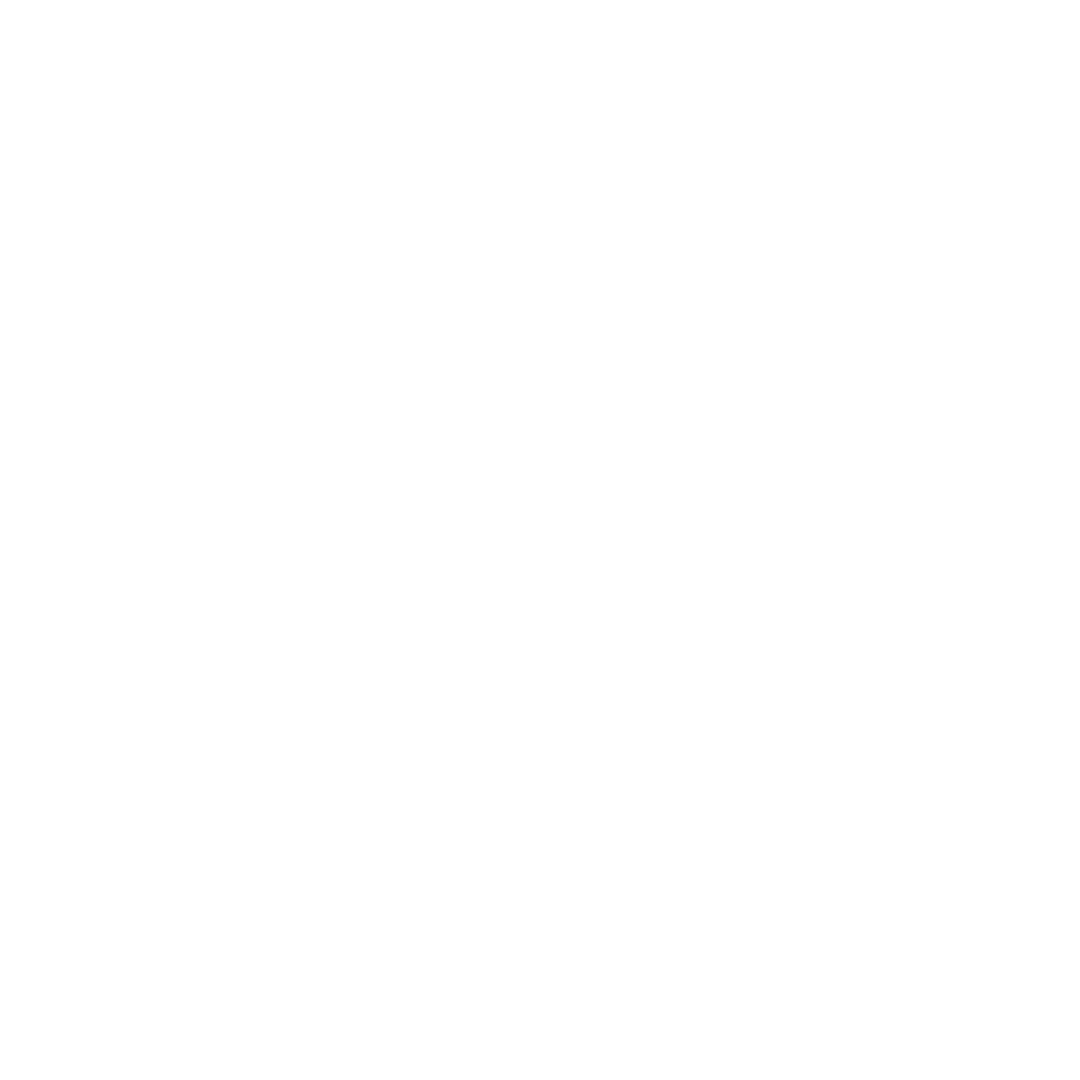

nox Control

- Standard

- Optional

CSP-NOXProp+

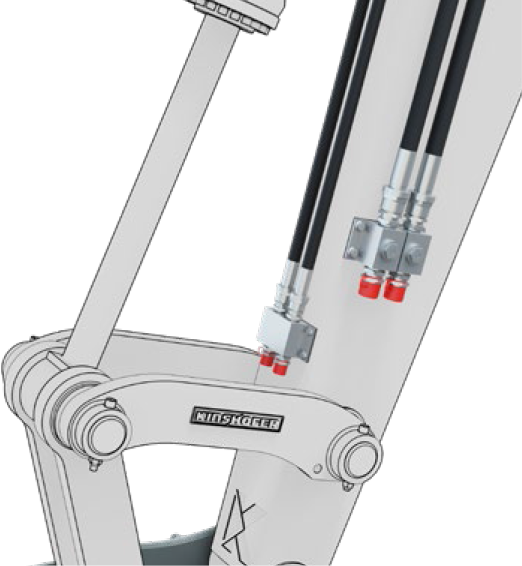

HYDRAULIC LINES

DF04

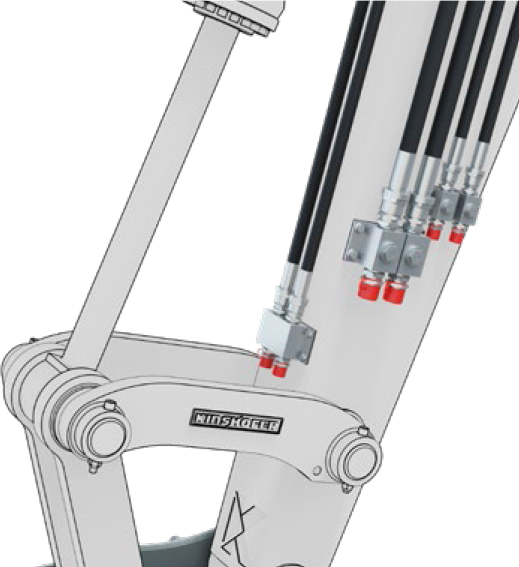

HYDRAULIC LINES

DF06

HYDRAULIC LINES

DF10

HYDRAULIC LINES

Always the right control system depending on the machine‘s hydraulic configuration

The table provides a quick overview on the different

functions and for which control system they are available.

Short summary on machine requirements:

CSP:

NOXProp+ Hammer/shear circuit

DF04

2 x proportional double-acting circuits

DF06

2 x proportional double-acting circuits (tilt and rotation) 1 x hydraulic quick coupler circuit

DF10

2 x proportional double-acting circuits (tilt and rotation) 1 x hydraulic quick coupler circuit 1 x double-acting high pressure circuit (compactor) 1 x double-acting low pressure circuit (gripper)

CSP:

NOXProp+ Hammer/shear circuit

DF04

2 x proportional double-acting circuits

DF06

2 x proportional double-acting circuits (tilt and rotation) 1 x hydraulic quick coupler circuit

DF10

2 x proportional double-acting circuits (tilt and rotation) 1 x hydraulic quick coupler circuit 1 x double-acting high pressure circuit (compactor) 1 x double-acting low pressure circuit (gripper)

NOXProp+ & NOXProp

CSP - CONTROL SYSTEM

Although this control system only requires one hydraulic function from the excavator, all Tiltrotator functions can be used at the same time. Also functions like steering/driving control, boom swing and dozer blade etc. can be controlled optionally. All functions are controlled proportionally and a separate control system is installed at the excavator. The joysticks of the machine will be replaced by new joysticks provided by KINSHOFER.

KEY FEATURES NOXProp+

NOXProp+

TOUCHSCREEN

MACHINE REQUIREMENTS

CSP - NOXProp+ & NOXProp

NOXProp

CONTROL UNIT

KEY FEATURES NOXProp

NOXProp+

Control system

The NOXProp+ control system provides more safety and precision. NOX Tiltrotator, quick coupler and attached tools are controlled effectively and conveniently with ergonomic joysticks by the smart NOXProp+. Easily retrofittable for each excavator.

Features are the individual function setting and the easy menu navigation thanks to the corresponding touchscreen. Integrated GPS, LTE, Bluetooth and WiFi link your machine with the digital workplace.

Features are the individual function setting and the easy menu navigation thanks to the corresponding touchscreen. Integrated GPS, LTE, Bluetooth and WiFi link your machine with the digital workplace.

BG-MODULE CONNECTOR

NOXProp+ & NOXProp

CSP - CONTROL SYSTEM

STANDARD-JOYSTICK

FRONT

NOXProp+ & NOXProp

CSP - CONTROL SYSTEM

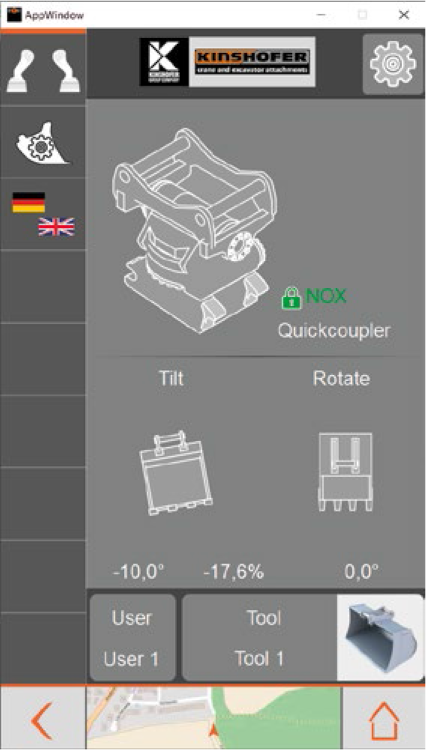

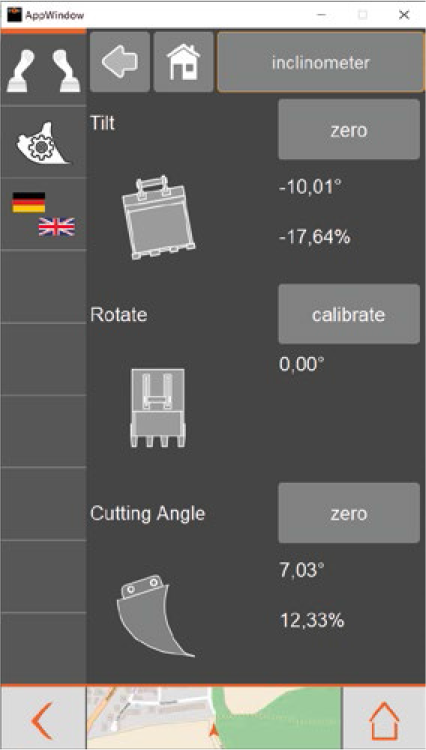

Home display

attachment & quick coupler

Geometry overview of

attachment and interface to

2D/3D systems

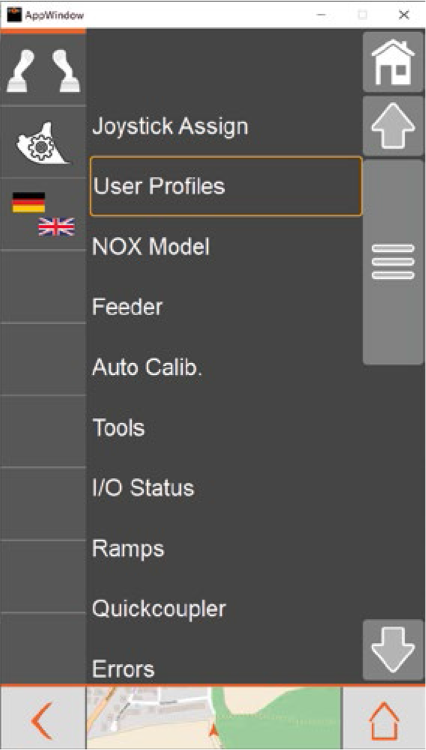

Easy and logical menu

navigation

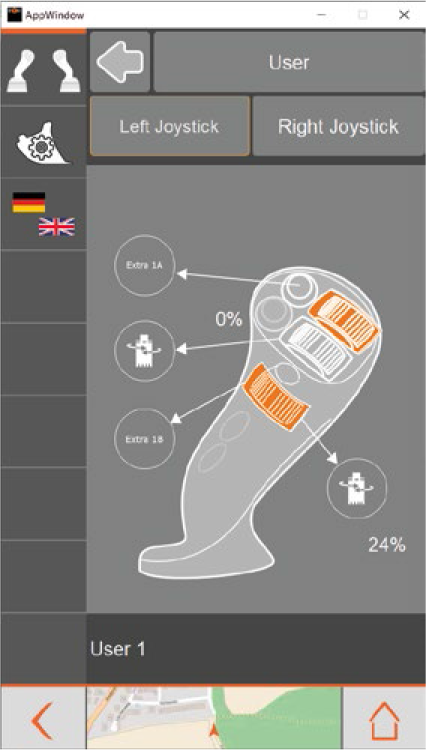

Individual function

configuration of joystick

buttons

STANDARD-JOYSTICK

BACK

Joysticks

The L8 is the multifunctional ergonomic joystick grip that

has set a new standard with its innovative, functional

design. You can control two roller functions simultaneously

with your thumb and index finger. Up to three rollers can be

installed, two for the thumb and one for the index finger.

On the grip there is room for up to nine buttons, meaning

that most functions can be gathered in a small area.

(Joysticks must be replaced when CSP – NOXProp+ or

NOXProp is installed.)

DF04

CONTROL SYSTEM

The DF04 control system requires 2 double-acting hydraulic circuits. Only two functions, e.g. rotation and tilting, can be realized simultaneously. In order to control the attachment or the quick coupler, one of the two hydraulic circuits is separated by a switch valve, installed on the NOX Tiltrotator. Therefore, up to two extra functions, e.g. quick coupler, can be realized.

MACHINE REQUIREMENTS FOR DF04

DF04 CONTROL UNIT

DF06

CONTROL SYSTEM

The DF06 control system requires 2 double-acting hydraulic circuits for the rotation and tilt movement of the NOX Tiltrotator. For the use of a hydraulic quick coupler, an additional circuit is required. The tilt function can be switched by pressing a button on the joystick to the extra function controlling e.g. the opening and closing of a grab.

MACHINE REQUIREMENTS FOR DF06

DF10

DIRECT FEED SYSTEM

The DF10 control system requires at least 2 double-acting hydraulic circuits for the rotation and tilt movement of the NOX Tiltrotator. Including the lines of the quick coupler function, two other hydraulic circuits, e.g. open/close grab and open/close intergrated gripper, can be connected to the NOX Tiltrotator. Furthermore, an additional drain line can be installed.

MACHINE REQUIREMENTS FOR DF10

DF04, DF06 & DF10 Control systems

- TILTROTATOR

- FLEXIBILITY

- CONTROL

- SENSORS

- ATTACHMENTS