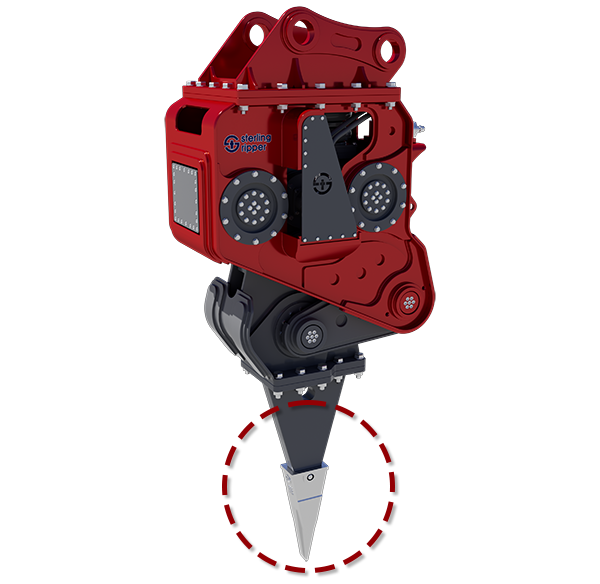

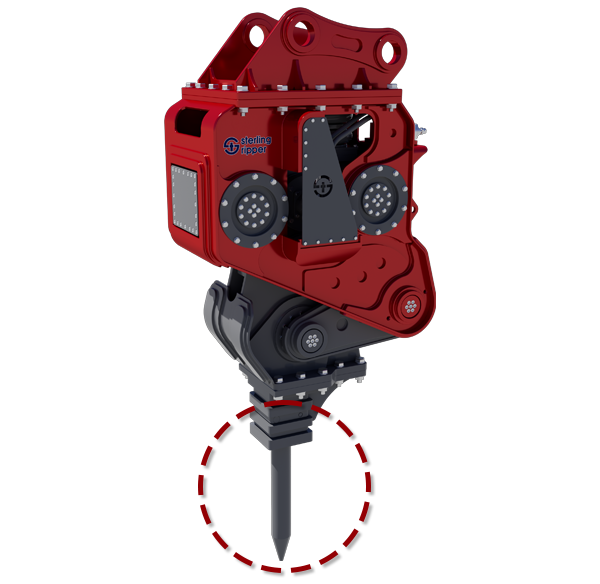

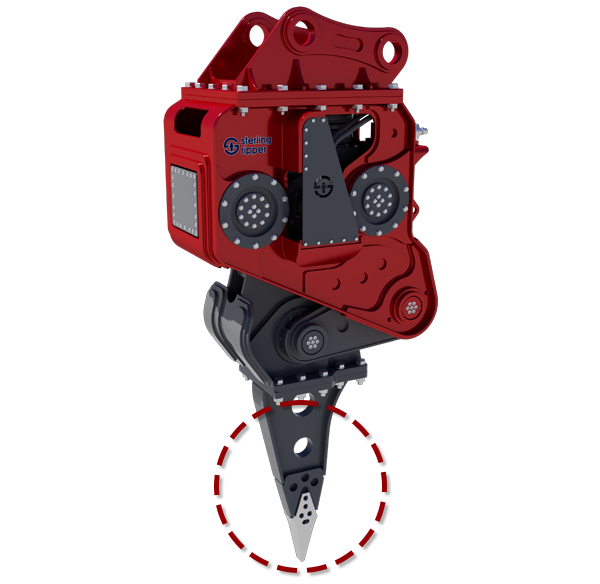

Sterling Ripper offers three options in Tooth type for soft & medium hard-rock, Chisel type for hard-rock for hard-rock, and Compactor type for compacting ground.

Single Sterling Ripper body has three optional tools! you can simply change it at site any time depending on rock types and various application!

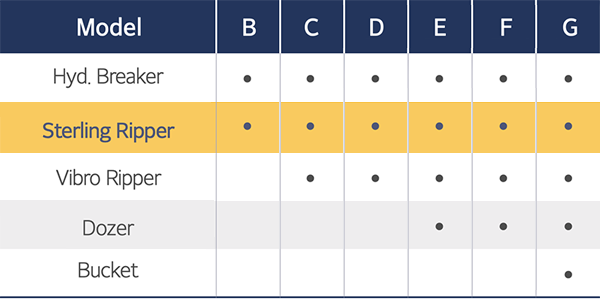

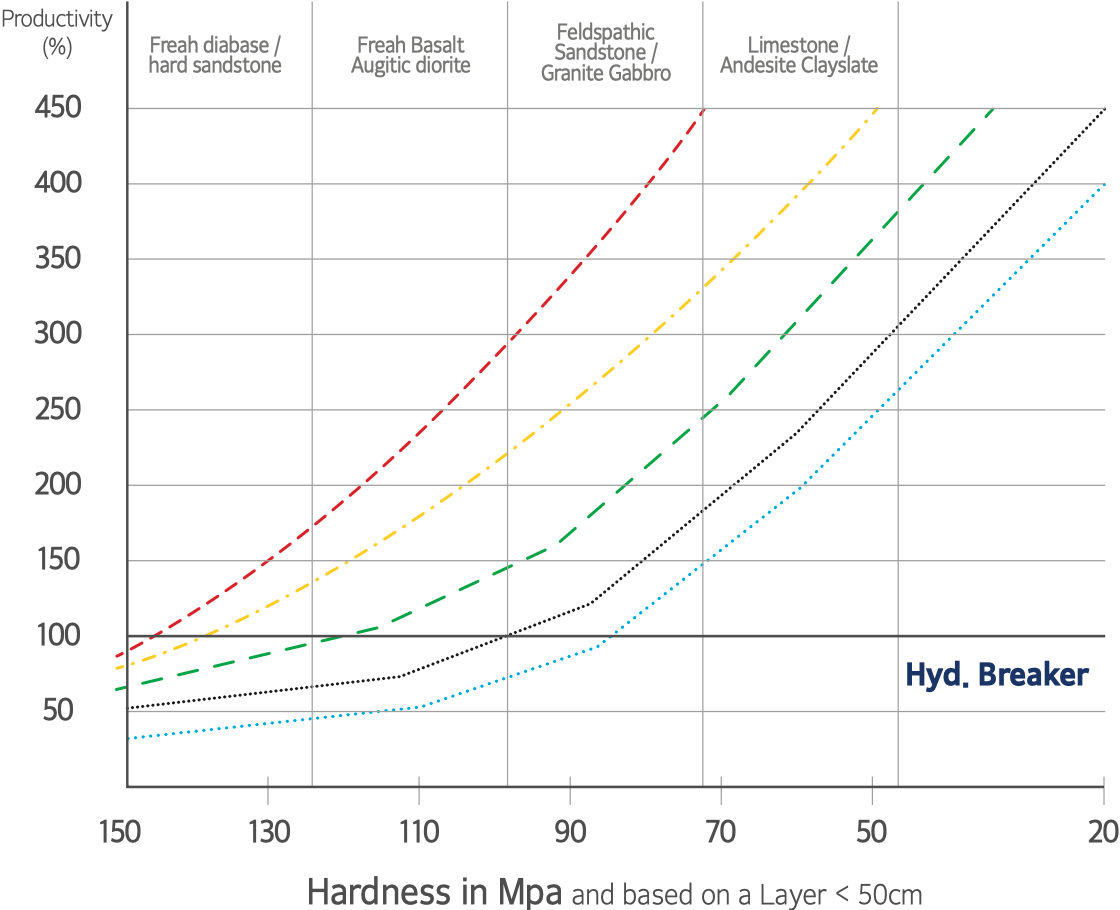

· Higher productivity than hydraulic breaker

– 2 ~ 8 times better productivity than hyd. breaker depending on type of rocks

· More powerful than other vibratory rippers

– Unique structure and design specially bigger and centered eccentric weight

– Sterling Ripper most powerful Ripper in the same class

· Selective tool options – Three tools for one Ripper

– Chisel type for hard rock, tooth type for soft & mid hard-rock and Compactor type for

compacting ground

– Three optional tools enables Sterling Ripper to offer wider selections of

application than competitors at rock breaking job sites

· Minimum vibration to excavator and operator at hard-rock

– Unique Cartilage-link of Sterling Ripper allows more powerful striking force

but less vibration transmitted to excavator and operator

– Less impact to excavator and less fatigue to operator

· Minimum noise

– Sterling Ripper’s Unique Cartilage-link structure technology allows minimum

noise at max. 90db and downtown building construction can be done without

restrictions

· Easy on-site maintenance & low maintenance cost

– Concise structure of components and structure

– Most parts can be replaced at job site

– No need to return it to repair shop

– Less number of parts than competitors enable low maintenance cost

– Maximum productivity can be achieved by reducing down time by on site

parts replacement and fast tooth replacement

· Under water operation without special devices

– All kinds of work under water can be done without any expensive and

complicated preparations